INSPECTION SOLUTIONS FOR THE FOOD INDUSTRY

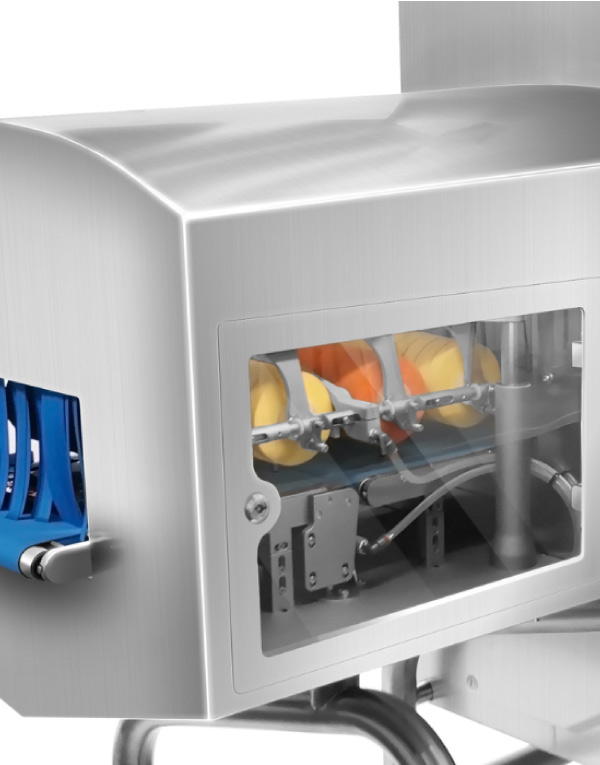

Our inspection systems are designed to meet the quality requirements of food manufacturing. With our inspection systems, you can ensure the quality of the product and improve your efficiency.

ALL-IN-ONE: MANY INSPECTIONS IN ONE SYSTEM

The revolution of quality control: all the inspection technologies you desire, in one, fully configurable system.

DIGITAL FACTORY: THE DATA DRIVEN PLANT MANAGEMENT TO ENHANCE PRODUCTIVITY

Discover the data intelligence platform designed by Antares Vision Group to support companies enhance line efficiency and production quality, improve planning and speed up agile decision-making.

DIAMIND

POWERING PRODUCTS AND SUPPLY CHAINS

The integrated, intelligent ecosystem of solutions to power products and supply chains, enabling a data-driven and tailored journey to digital innovation.

Connecting physical products with digital identities, DIAMIND runs at the line, factory, warehouse, enterprise, and supply chain levels, and guarantees product quality (inspection systems and equipment) and end-to-end traceability through integrated and cloud data management.

DIAMIND SOLUTIONS

NEWS

![Home [5] - Antares Vision Group](https://antaresvisiongroup.com/food/wp-content/uploads/2024/02/4.png)

Packexpo Chicago

![Home [6] - Antares Vision Group](https://antaresvisiongroup.com/food/wp-content/uploads/2024/02/6.png)

Drinktec Technology

![Home [7] - Antares Vision Group](https://antaresvisiongroup.com/food/wp-content/uploads/2024/02/3.png)

Fispal

![Home [8] - Antares Vision Group](https://antaresvisiongroup.com/food/wp-content/uploads/2024/02/8.png)

Propak Asia

![Home [9] - Antares Vision Group](https://antaresvisiongroup.com/food/wp-content/uploads/2024/02/7.png)

Hispack

![Home [10] - Antares Vision Group](https://antaresvisiongroup.com/food/wp-content/uploads/2024/02/11.png)

Cheese Expo

![Home [11] - Antares Vision Group](https://antaresvisiongroup.com/food/wp-content/uploads/2024/01/Progetto-senza-titolo-90.png)